A farewell to rattle: How MOUNTAIN sets a new standard for keyboard sound

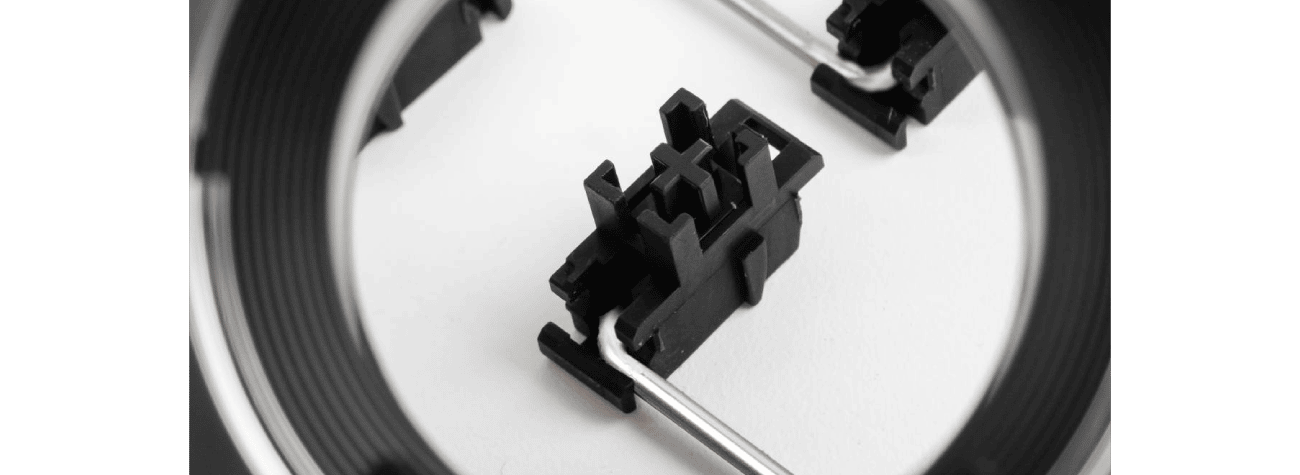

Think of mechanical keyboards and you will soon think about the distinctive sound created by mechanical switches, which are a deciding factor in the auditory experience. Often overlooked are the stabilizers, which are assemblies made of plastic and metal wire to balance extra-wide keys such as Shift, Space, Backspace and Enter.

Way too many mechanical keyboards are plagued by low-quality stabilizers that create a dreaded rattle sound when said extra-wide keys would be actuated, effectively ruining the typing and gaming experience with an assault to the users’ ears.

We at MOUNTAIN believe that to be unacceptable and thus considerably upped the ante for a premium keyboard’s stabilizer game, as far back as our debut flagship keyboard Everest, as well as our most recent Everest 60.

The first ingredient is premium material. The German manufacturer Cherry not only produces high quality switches, but they’re also the gold standard for plate-mounted stabilizers, working with tighter tolerances and high-quality components, allowing for a more pleasant and muted sound profile.

It doesn’t end there. Not only do we choose the premier supplier for the job with Cherry, but we’re also taking a page out of the enthusiast’s playbook by factory-lubricating them. What does that mean in practice?

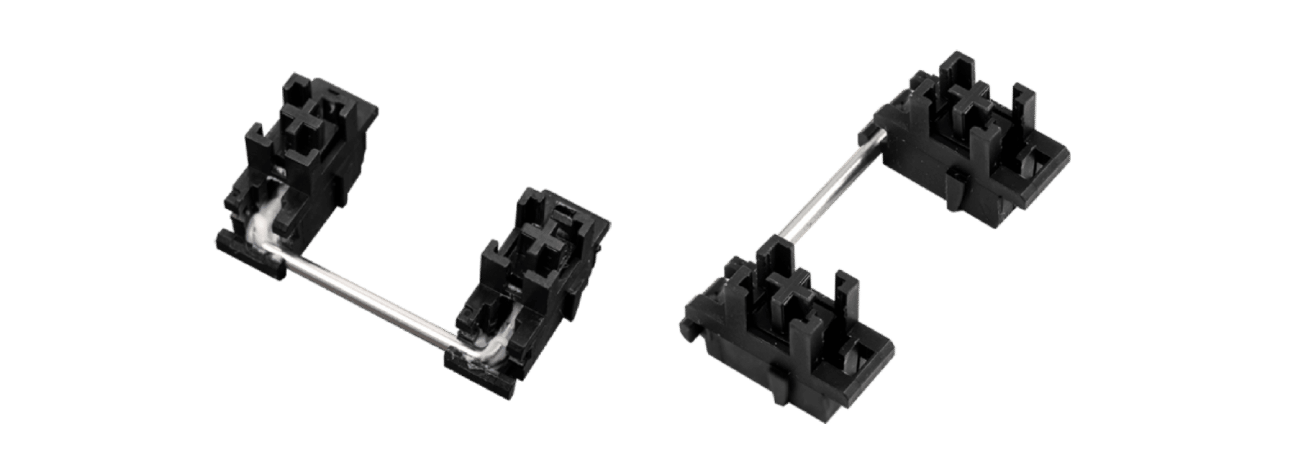

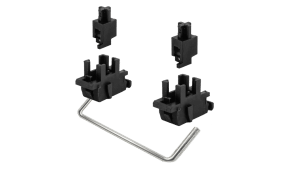

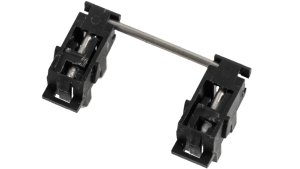

The stabilizers are being disassembled into their individual parts, consisting of:

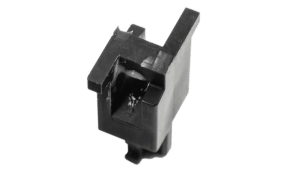

Two stabilizer housings

Two stabilizer stems

One stabilizer wire

All of these are moving parts, interacting with each other, producing noise in the process. To mute this, we’re applying industrial-grade lubrication where the individual components touch. Just a thin layer of lubrication, barely visible, but enough to reduce friction and dampen mechanical collision.

Topping off the MOUNTAIN stabilizer experience is a small extra step called “clipping”. Cherry stabilizers have a unique feature, a set of extremely thin plastic feet at the bottom of the stabilizer housings. These are supposed to cushion the impact when you bottom-out with a keystroke.

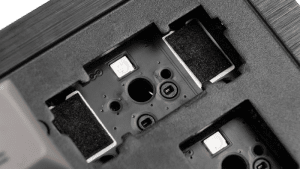

While the idea of cushioning bottom-out actuations is great, we went a different route to achieve that on Everest 60. We manually clip these tiny feet off and instead place a small pad underneath the stabilizers on the PCB, effectively improving the idea on two fronts: These plastic feet would make direct contact with the PCB, which causes unnecessary stress to the material. At the same time, soft pads improve the cushioning concept by providing a softer landing space.

What may sound relatively mundane includes quite a bit of manual labor if you do all this by yourself, but the effect is oh-so-great. If you take nothing else away from this text, rest assured that once you have experienced properly tuned stabilizers, there’s no turning back. What gave the impression of throwing a screw in a bag with other screws now sounds muted and pleasant, no longer being in the way of your switches’ and ultimately your keyboard’s sound profile.